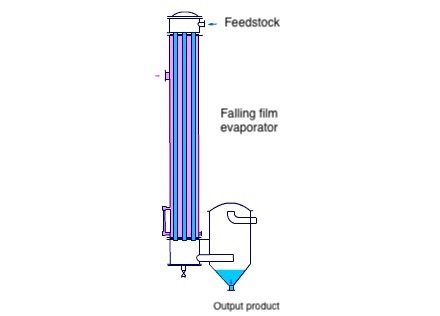

Principle of falling film evaporator

The big difference between the falling film evaporator and the rising film evaporator is that the flowing direction is downwards rather than upwards, and that causes big changes of the operation condition of the falling film evaporator:

1. For filling film evaporator, evaporation happens in the heating tube, and it is generally divided into 6 stages, including preheating stage, bubble generation stage, emulsification stage, conversion stage, film forming stage, and steam stage. The flow velocity of raw material liquid in the falling film evaporator must be controlled, otherwise the 1st to 4th stage (1. preheating stage; 2. bubble generation stage; 3. emulsification stage; 4. conversion stage) could not be finished in the short time, and the film was failed to be formed. Previously, it is discussed that conditions of film formation, thereinto, a certain gas-liquid ratio must be controlled, otherwise the film could not be formed due to small amount of gas. This is why a liquid distributor must be set on the top of each heating tube.

2. In the falling film evaporator, the flow rate of the material is greater than that of the rising film evaporator, which is conducive to film formation, so the evaporation efficiency was not smaller than that of the rising film evaporator under condition of controlled input flow rate.

3. In the falling film evaporator, the heating tubes were not filled with material, the heat transfer efficiency is higher than the rising film evaporator from the 1ststage preheating stage, so the evaporation efficiency of falling film evaporator does not decrease due to the fast flow rate of the material liquid.

4. In the falling film evaporator, the amount and flow rate of gas required for film formation is less because of the fast flow rate of material, which is also conducive to guarantee the evaporation efficiency of the falling film evaporator.

Improvement of falling film evaporator

From the above discussion, it is known that flowing in film state is the key to the falling film evaporator. So the improvement of the evaporation efficiency of the falling film evaporator, shall start from it.

Obviously, controlling the flow rate of material and the uniformity of film flow are the key to improve the evaporation efficiency of the falling film evaporator:

In conclusion, the following solution can be adopted for improvement of the evaporation efficiency of the falling film evaporator:

1. Improve the liquid distributor, optimize the flow velocity of material liquid and the uniformity of film flow.

2. High operation requirements on the falling film evaporator, so the automatic control has a great impact on the evaporation efficiency.

Contact US

Reach out to an optimized proposal