Abstract

In the lead – up to the delivery of equipment for a crucial molasses ethanol production project, our factory recently hosted a factory inspection and acceptance by an Australian company. This factory inspection and acceptance was not only a vital step in ensuring the equipment’s quality but also a testament to our commitment to delivering high-quality products in our long – standing cooperation.

Introduction

The equipment set for the molasses ethanol production project included essential equipments such as a single-effect falling film evaporator, several mixing tanks and storage tanks, and other auxiliary equipments. The single-effect falling film evaporator is designed to efficiently remove water from the molasses raw materials, thereby increasing the molasses concentration. Given the heat – sensitive nature of the molasses, a single – effect design is adopted, this approach helps to reduce the working temperature, which is crucial for maintaining the active ingredients in the molasses.

The main aspects of the equipment inspection and acceptance are as follows:

A. Equipment Integrity Check: This aims to ensure that both the varieties and quantities of actual equipments provide are in line with the agreed – upon terms.

B.Technical Drawing and Specification Verification: The actual equipment is meticulously compared with the technical drawings and specifications jointly determined by both parties. Every detail, including each dimension, the orientation of nozzles, surface treatment, etc., must match the drawings precisely. Also, the materials used for the equipment should meet the stipulated requirements. This thorough verification guarantees that the equipment is manufactured exactly as designed.

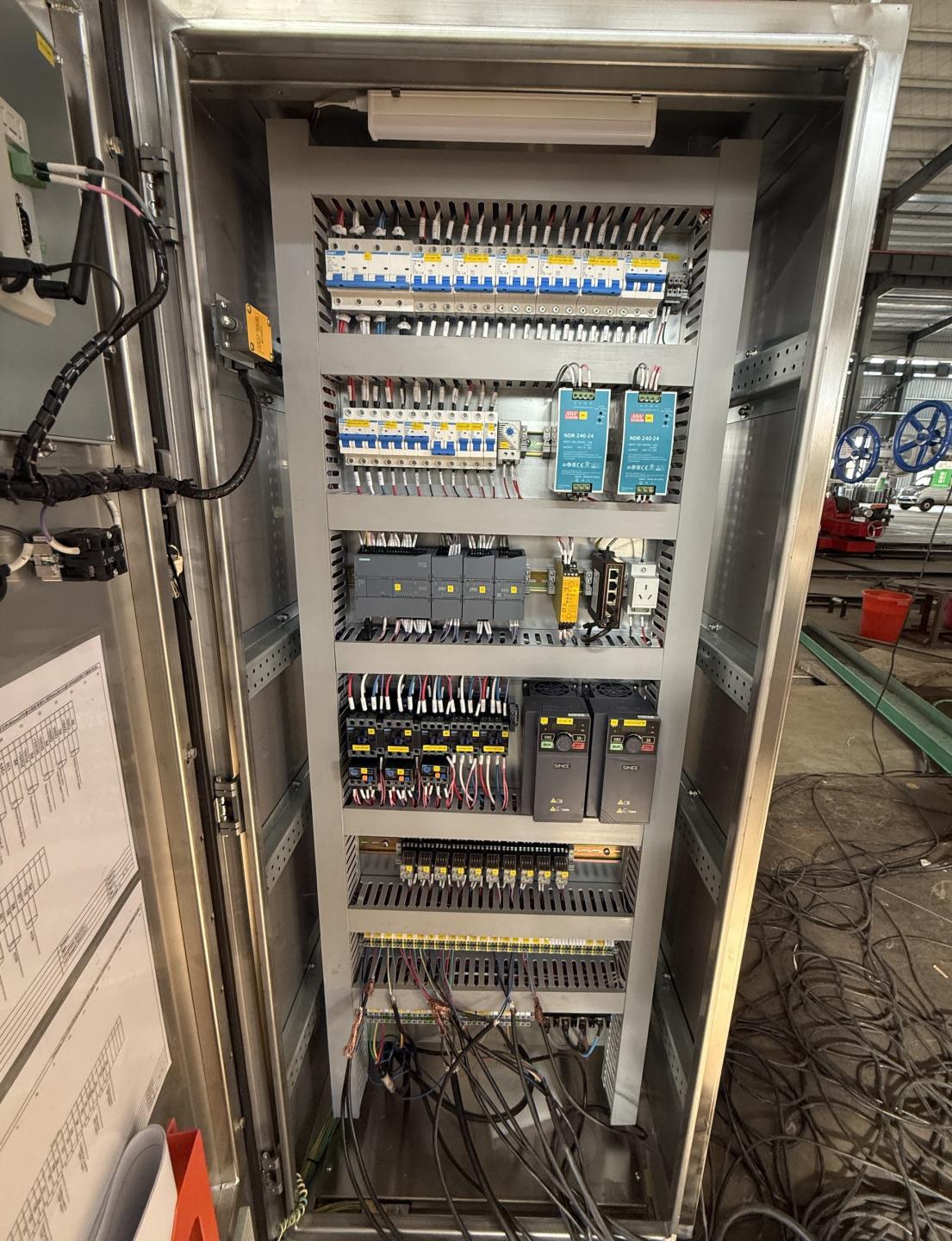

C. Consideration of Electrical Standard Differences: Based on past cooperation experience, there are differences in electrical standards between China and Australia, especially in aspects such as voltage levels, grounding systems, and electrical safety regulations. Therefore, special attention is paid to the electrical components of the equipment. The rated voltage of the motors, the explosion – proof certification of the motors, the design of the operation control panels, and the installation of grounding wires are all inspected. Our technical team was on – site to explain how we made the necessary adjustments to comply with Australian electrical regulations while ensuring that the overall performance of the equipment remained unaffected.

This successful factory inspection and acceptance not only strengthened the trust and cooperation between the two parties but also laid a solid foundation for future business expansion. We look forward to further cooperation with the Australian client. We are committed to providing them with more reliable equipment and comprehensive services, jointly exploring broader prospects in the Australian market.

Contact Us

Please feel free to reach out for a reliable partner of next project.